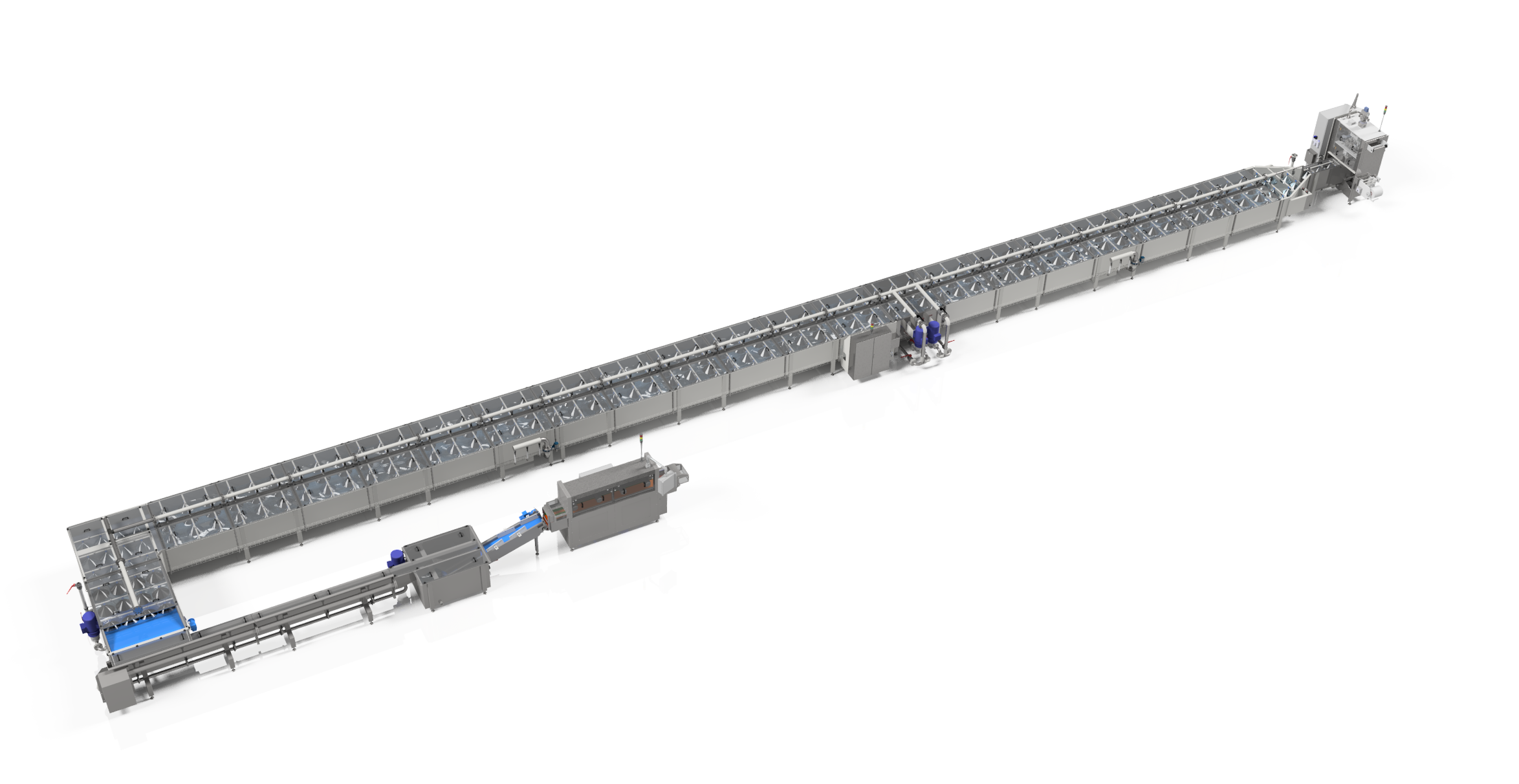

The Vermee-cooling system has been “state-of-the-art” for decades: full process control with cost reduced and automated production. This is both for mass production between 600kg/h – 2.500kg/h, initial production with precise products (after manual processing with silicone paper) and for special equipment for product development (e.g. in development laboratories) with max. 50kg/h possible.

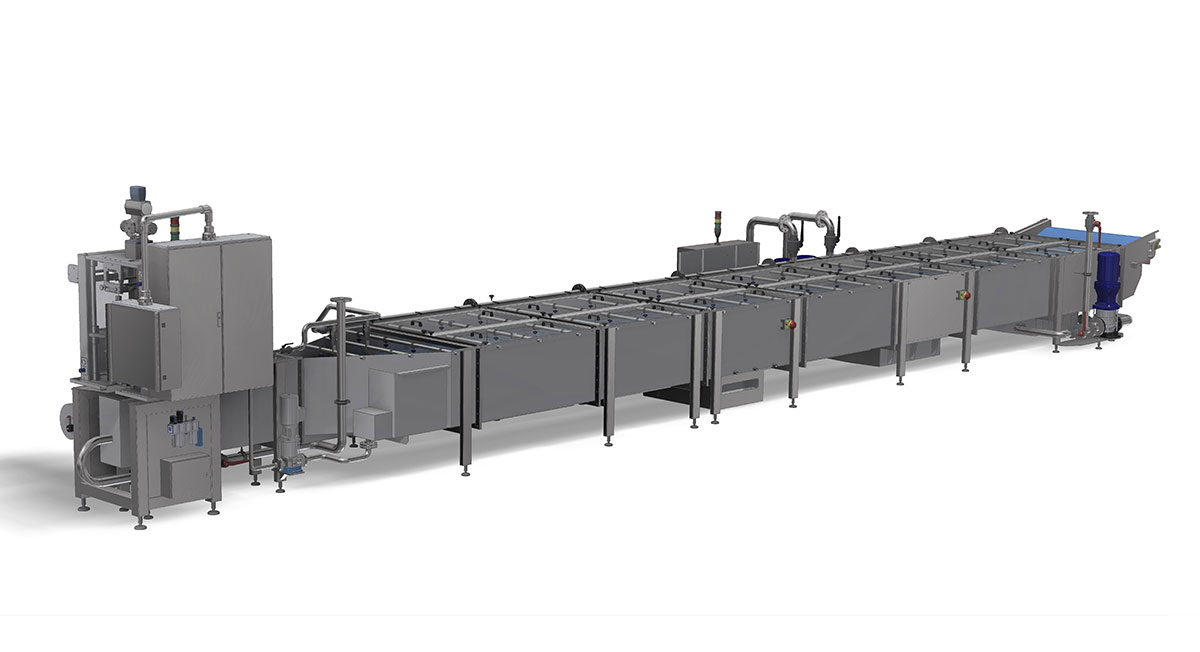

The automated cooling system transports, after filling by a vertical pouch filler / a hotmelt packaging machine, hot product pouches in a controlled water flow within approx. 40 minutes (depending on the filling temperature) to the discharge, where they can be cooled packed (without space-consuming cooling spaces). This unique technology adapts in many ways to individual production conditions:

Would you like to learn more about your cost saving opportunities or development scope via automated cooling? Please contact us!

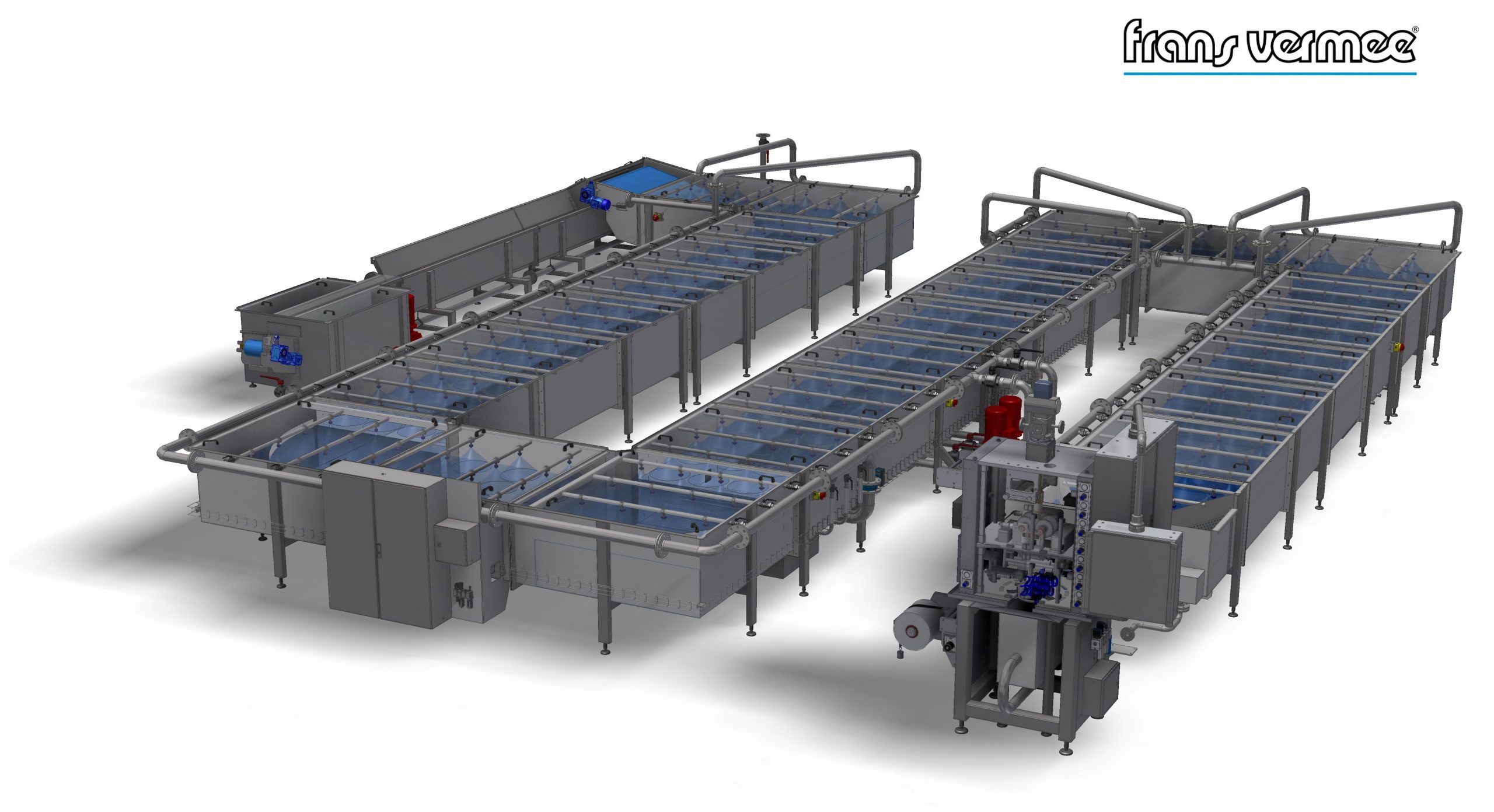

Fully integrated complete solution – from cooling to the end product ready for shipment

Thinking holistically, we offer fully integrated complete solutions. The Vermee solution portfolio includes automatic water treatment for the cooling water as well as further processing of the cooled end products. After cooling, the products can be separated or blown off and prepared directly for shipment for a simplified supply chain to your end customers. On request, we also integrate a pick-and-place system with a connected carton erector, precise packaging solution and palletizing. In addition to low unit costs, this maximizes the savings potential of personnel costs and increases process control for trouble-free operations.