Vermee guides you competently through the multitude of technical details and interfaces regarding your filling and packaging requirements. The focus is on your end product and not on our systems and we translate the packaging relevant questions for you. In this way, you quickly arrive at an integrated solution and a transparent basis for decision-making.

Please contact us

Here is a selection of basic components

to be clarified for your

filling and packaging machine:

- Flowability of the product masses,

- Microbiological or chemical reactions with desired shelf life,

- Performance spectrum (e.g. cycles per minute, production quantities, utilization rates, etc.)

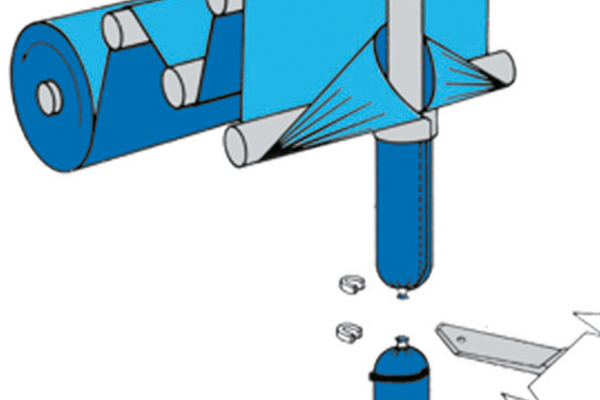

- Packaging materials (e.g. meltable flat films, PVDC-free films, PVDC films, cellophane films, aluminum composite films, mono films, multilayer films, perforated films, etc.) outer packaging such as flow pack, cardboard box, etc., containers such as PET or glass bottles, R-PET cups, etc.),

- Closures (e.g. round wire clips, re-closable caps, product displacement, etc.)

- Type of seal (e.g. hot air, jaw-sealing, high frequency, ultrasonic, extrusion, etc.),

- Registration accessory for precise labeling, weight checks, detectors, etc.

- Interfaces for product supply via pumps, product valves, etc. as well as thermal post-treatment such as automated cooling, cooking- or sterilization and pasteurization processes.

And individualization options

regarding to filling and packaging:

- Attachment of an opening aid to primary packaging, such as snacks for kids

- 2-component filling with different product viscosities, as for curds and jam, automated high performance production of e.g. adhesives, hot melts or bitumen

- additional gas-flushing or venting, e.g. for explosives or sealants

- Product development of new physical states, such as nanocellulose

- Development of pilot systems, e.g. for fruit juice concentrate, adhesive production, etc.

- Contract filling of fresh products, such as filling of fruit juices, multi-layer purees, cold cuts, etc.